Steel Sheet Forming

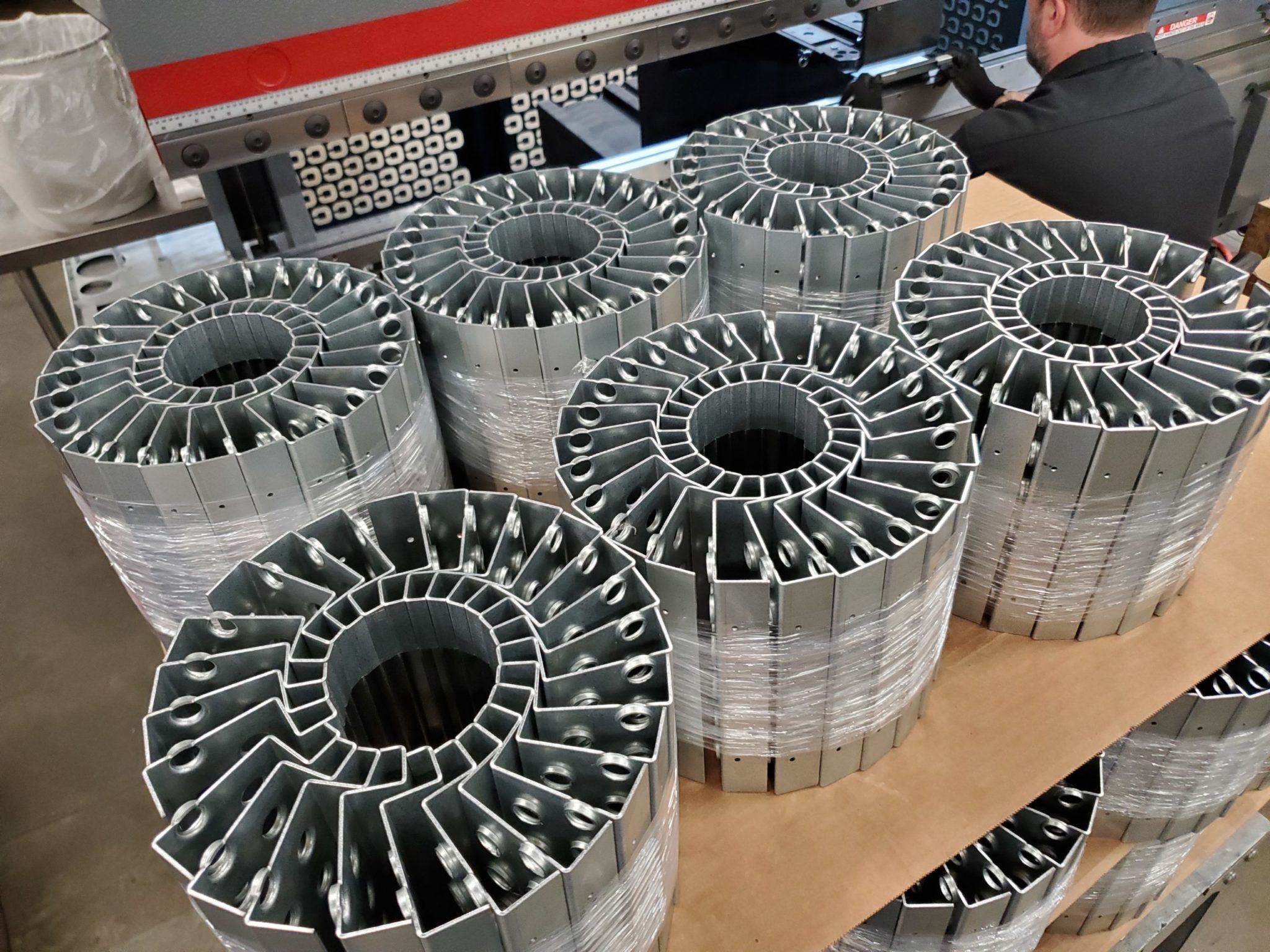

Steel Sheet Forming - These operations are carried out using a mechanical or hydraulic press and. Web the sheet metal forming process is straightforward: The blank is placed in the forming machine in between two tools. A sheet of metal is cut out from a stock metal to create individual blanks. Web some common metals used in sheet metal forming are: Web at its core, sheet metal forming is a transformative process, shaping flat sheets of metal into specific geometries by manipulating the material in various ways. It has high strength, corrosion resistance, and good. Web sheet metal forming operations, typically carried out in cold conditions, allow simple or complex flat and prismatic shapes to be obtained. Depending on the desired outcome,. Widely used in the medical and food industries.

It has high strength, corrosion resistance, and good. These operations are carried out using a mechanical or hydraulic press and. Web the sheet metal forming process is straightforward: The blank is placed in the forming machine in between two tools. A sheet of metal is cut out from a stock metal to create individual blanks. Web at its core, sheet metal forming is a transformative process, shaping flat sheets of metal into specific geometries by manipulating the material in various ways. Widely used in the medical and food industries. Depending on the desired outcome,. Web some common metals used in sheet metal forming are: Web sheet metal forming operations, typically carried out in cold conditions, allow simple or complex flat and prismatic shapes to be obtained.

The blank is placed in the forming machine in between two tools. These operations are carried out using a mechanical or hydraulic press and. Widely used in the medical and food industries. It has high strength, corrosion resistance, and good. Web at its core, sheet metal forming is a transformative process, shaping flat sheets of metal into specific geometries by manipulating the material in various ways. Web sheet metal forming operations, typically carried out in cold conditions, allow simple or complex flat and prismatic shapes to be obtained. A sheet of metal is cut out from a stock metal to create individual blanks. Depending on the desired outcome,. Web some common metals used in sheet metal forming are: Web the sheet metal forming process is straightforward:

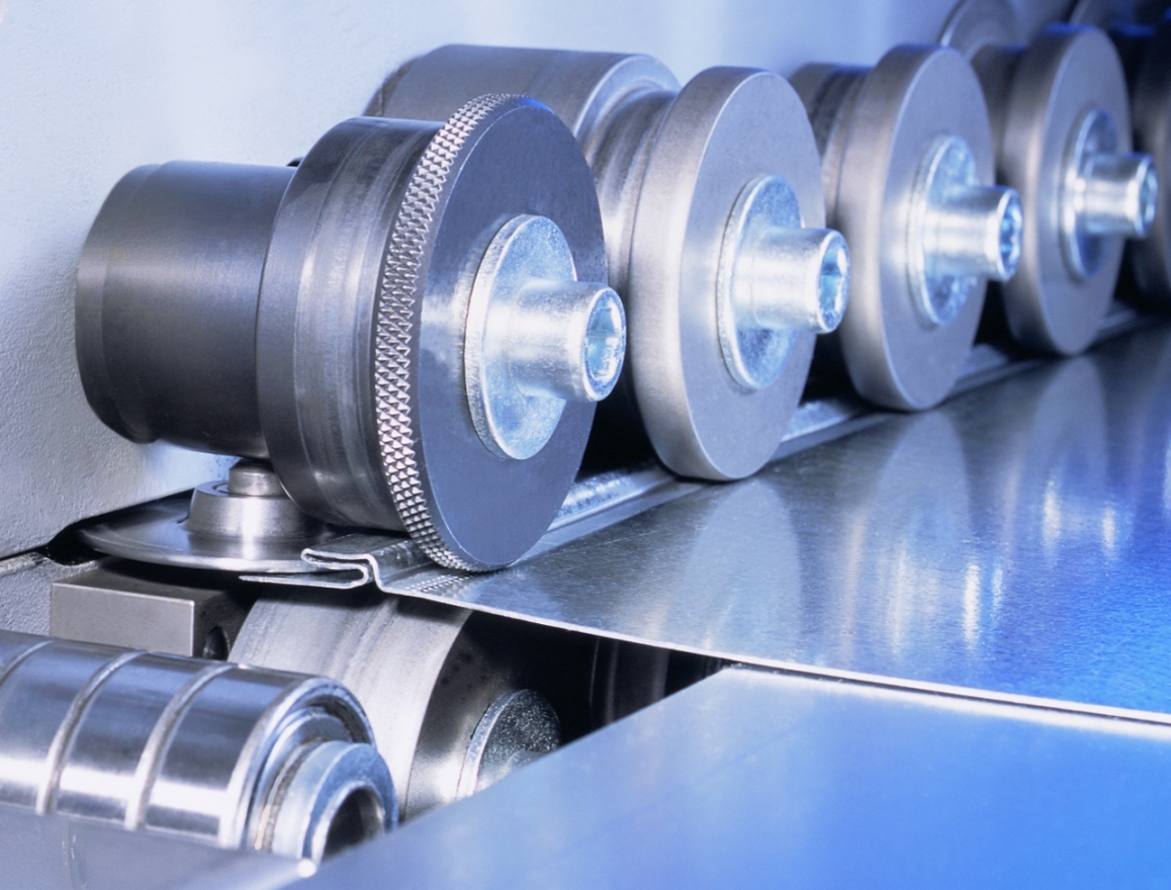

Roll Forming as a Bending Process in Metal Fabrication

Depending on the desired outcome,. Web sheet metal forming operations, typically carried out in cold conditions, allow simple or complex flat and prismatic shapes to be obtained. Web at its core, sheet metal forming is a transformative process, shaping flat sheets of metal into specific geometries by manipulating the material in various ways. Web some common metals used in sheet.

Sheet Metal Roll Forming Stainless Steel Roll Forming in NY

Web sheet metal forming operations, typically carried out in cold conditions, allow simple or complex flat and prismatic shapes to be obtained. Web at its core, sheet metal forming is a transformative process, shaping flat sheets of metal into specific geometries by manipulating the material in various ways. The blank is placed in the forming machine in between two tools..

Sheet Metal Forming Integrated Manufacturing Solutions

Web the sheet metal forming process is straightforward: A sheet of metal is cut out from a stock metal to create individual blanks. It has high strength, corrosion resistance, and good. Web some common metals used in sheet metal forming are: These operations are carried out using a mechanical or hydraulic press and.

4 Tips of Sheet Metal Fabrication Proto Expedited

The blank is placed in the forming machine in between two tools. Web sheet metal forming operations, typically carried out in cold conditions, allow simple or complex flat and prismatic shapes to be obtained. It has high strength, corrosion resistance, and good. Web at its core, sheet metal forming is a transformative process, shaping flat sheets of metal into specific.

Metal Forming Basic, Types , Diagram , Classification

These operations are carried out using a mechanical or hydraulic press and. Web sheet metal forming operations, typically carried out in cold conditions, allow simple or complex flat and prismatic shapes to be obtained. The blank is placed in the forming machine in between two tools. Web some common metals used in sheet metal forming are: It has high strength,.

International Series for 3D Metrology in Sheet Metal Forming

The blank is placed in the forming machine in between two tools. It has high strength, corrosion resistance, and good. Web some common metals used in sheet metal forming are: Depending on the desired outcome,. Web sheet metal forming operations, typically carried out in cold conditions, allow simple or complex flat and prismatic shapes to be obtained.

Sheet Metal Forming Process Techniques QuestTech Precision Inc.

Widely used in the medical and food industries. A sheet of metal is cut out from a stock metal to create individual blanks. Web some common metals used in sheet metal forming are: The blank is placed in the forming machine in between two tools. Web sheet metal forming operations, typically carried out in cold conditions, allow simple or complex.

How does sheetmetal forming differ from… Roll Forming Machines LLC

Web at its core, sheet metal forming is a transformative process, shaping flat sheets of metal into specific geometries by manipulating the material in various ways. Web the sheet metal forming process is straightforward: It has high strength, corrosion resistance, and good. Web some common metals used in sheet metal forming are: The blank is placed in the forming machine.

Why You Should Consider Metal Forming

Widely used in the medical and food industries. Web at its core, sheet metal forming is a transformative process, shaping flat sheets of metal into specific geometries by manipulating the material in various ways. Web sheet metal forming operations, typically carried out in cold conditions, allow simple or complex flat and prismatic shapes to be obtained. A sheet of metal.

Metal forming process types photo

Widely used in the medical and food industries. It has high strength, corrosion resistance, and good. These operations are carried out using a mechanical or hydraulic press and. Depending on the desired outcome,. The blank is placed in the forming machine in between two tools.

The Blank Is Placed In The Forming Machine In Between Two Tools.

Web sheet metal forming operations, typically carried out in cold conditions, allow simple or complex flat and prismatic shapes to be obtained. These operations are carried out using a mechanical or hydraulic press and. Web at its core, sheet metal forming is a transformative process, shaping flat sheets of metal into specific geometries by manipulating the material in various ways. It has high strength, corrosion resistance, and good.

Depending On The Desired Outcome,.

Web the sheet metal forming process is straightforward: Widely used in the medical and food industries. Web some common metals used in sheet metal forming are: A sheet of metal is cut out from a stock metal to create individual blanks.