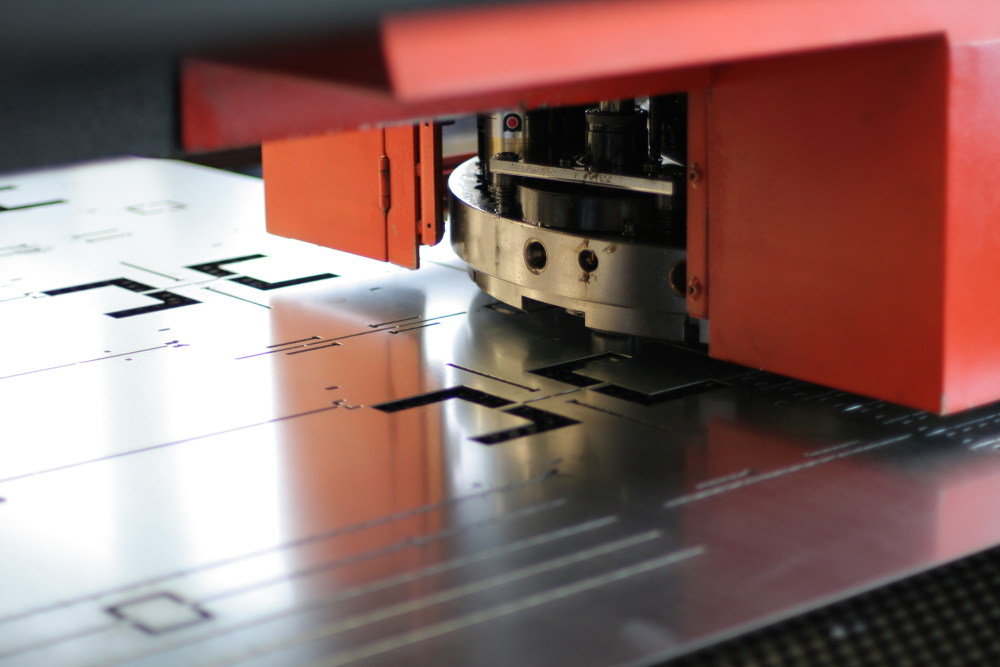

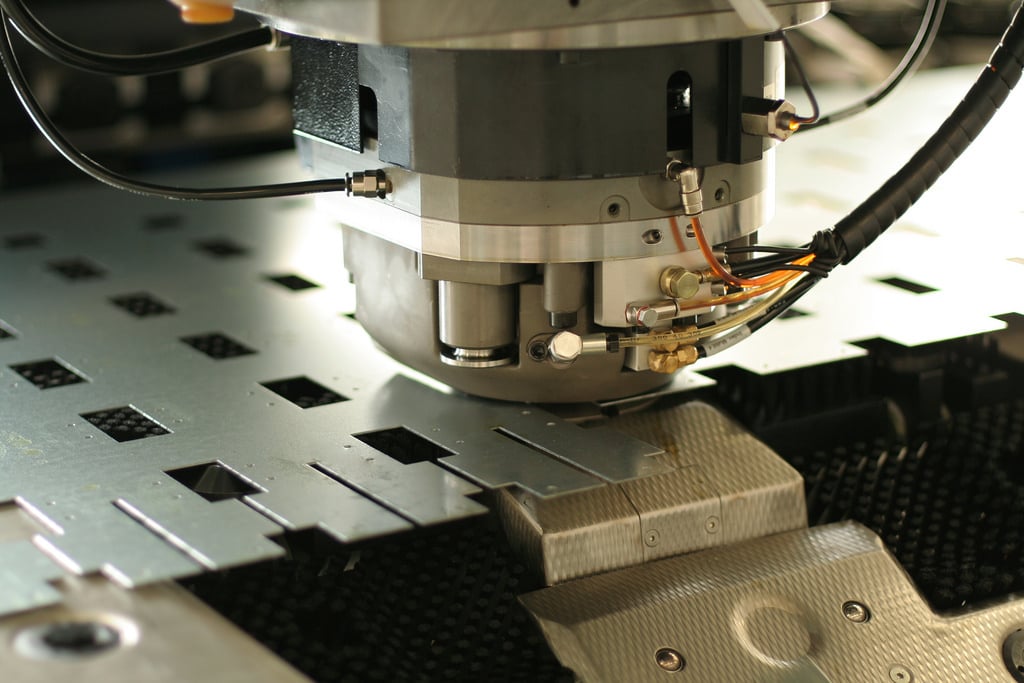

Sheet Metal Stamping Process

Sheet Metal Stamping Process - Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized. Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms. Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help.

Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms. Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help. Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized.

Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms. Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help. Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized.

What is Metal Stamping? A Guide to Processes, Steps and Types of

Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized. Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help. Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms.

Knead pliant Curcan metal stamping process Deasupra capului și umărului

Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help. Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms. Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized.

Metal Punching & Stamping Quality Sheet Metal Inc.

Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized. Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms. Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help.

Providing the Metal Stamping Industry with Wire Products

Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms. Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help. Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized.

Sheet Metal Stamping Forming Process Advantages And Disadvantages Bit

Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms. Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help. Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized.

Sheet Metal Stamping Process Aranda Tooling

Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms. Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help. Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized.

Understanding Sheet Metal Stamping Process INSCMagazine

Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help. Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized. Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms.

Knead pliant Curcan metal stamping process Deasupra capului și umărului

Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help. Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms. Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized.

Sheet Metal Stamping Forming Process Advantages And Disadvantages Bit

Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help. Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms. Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized.

Progressive Die Stamping Design Tips for Sheet Metal Komaspec

Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized. Web metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms. Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help.

Web Metal Stamping Is An Incredibly Versatile And Efficient Manufacturing Process That Takes Flat Metal Sheets Or Coils And Transforms.

Web metal stamping consists of a group of processes for the shaping and cutting of metal sheets using specialized. Web stamping is a manufacturing approach that converts coils or sheets of metal into desired geometry with the help.